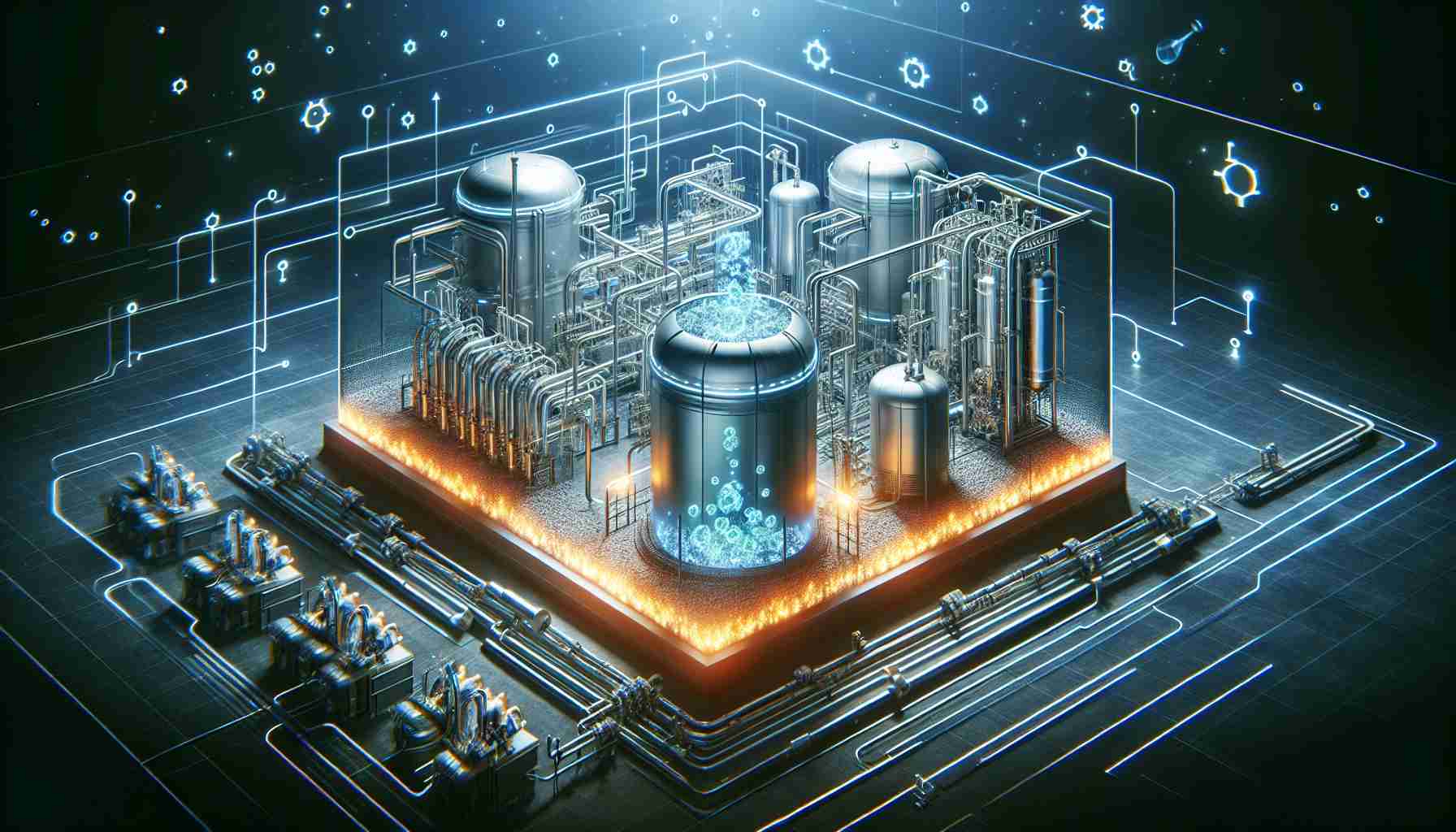

Haffner Energy is set to make a significant impact on the renewable energy landscape by initiating hydrogen production from organic waste at its state-of-the-art facility in Marolles Champagne, France. After a thorough year of innovative development, the plant is outfitted with the latest industrial production technologies, specifically engineered for continuous operation, ensuring optimal efficiency for approximately 8,000 hours annually.

The facility’s groundbreaking method hinges on thermolysis, a process that converts organic waste into usable hydrogen efficiently. With a planned output of 15 kilograms of high-purity hydrogen per hour, this translates to an impressive annual production of nearly 120 tonnes. Such a level of production equates to the energy required for hydrogen vehicles to travel over 12 million kilometers.

Haffner Energy’s commitment to sustainability highlights an essential shift towards cleaner mobility solutions. As governments and industries pivot away from fossil fuels, the production of mobility-grade hydrogen provides a much-needed alternative, capable of fueling a range of applications, particularly in transportation. This venture reflects a growing trend in which organic waste, often seen as a liability, is reimagined as a valuable resource, underscoring the potential for circular economy practices in the energy sector. This initiative not only addresses waste management but also advances the transition to a more sustainable future powered by renewable resources.

FAQ Section

1. What is Haffner Energy’s new initiative?

Haffner Energy is launching a hydrogen production facility in Marolles Champagne, France, utilizing organic waste to produce high-purity hydrogen.

2. What technology is being used at the facility?

The facility employs thermolysis, a process that efficiently converts organic waste into hydrogen. It is equipped with the latest industrial production technologies for continuous operation.

3. How much hydrogen will the facility produce?

The plant is planned to produce 15 kilograms of high-purity hydrogen per hour, which amounts to nearly 120 tonnes annually.

4. What are the environmental benefits of this initiative?

This hydrogen production offers a sustainable alternative to fossil fuels, contributing to cleaner mobility solutions and waste management while supporting a circular economy approach in the energy sector.

5. How does this initiative impact hydrogen vehicles?

The annual production of hydrogen from this facility translates to the energy needed for hydrogen vehicles to travel over 12 million kilometers, supporting the growth of hydrogen as an energy source in transportation.

Key Terms and Jargon Definitions

– Thermolysis: A chemical decomposition process caused by heat, which in this context is used to convert organic waste into hydrogen.

– High-purity hydrogen: Hydrogen that has been refined to remove impurities, making it suitable for use in various applications, including fuel cells and hydrogen vehicles.

– Circular economy: An economic model aimed at minimizing waste and making the most of resources, where products, materials, and resources are reused, recycled, or repaired.

– Sustainability: The ability to maintain ecological and social balance by utilizing resources responsibly without compromising the needs of future generations.

Related Links

Haffner Energy

European Union

International Renewable Energy Agency